Pipe fittings are essential components used in piping systems to connect, redirect, or modify the flow of fluids (liquids, gases, or slurries). They help in joining pipes of the same or different sizes, shapes, and materials, ensuring the efficient and secure transport of substances. These fittings play a crucial role in creating robust and leak-proof systems for industrial, residential, and commercial applications.

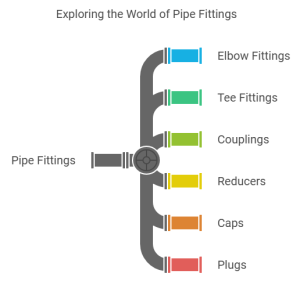

Different types of pipe fittings and their functions are explained below.

- Elbow

- Tee

- Reducer

- Union

- Coupling

- Adapters

- Olet (Weldolet, Sockolet, Elbowlet, Thredolet, Nipolet, Letrolet, Swepolet)

- Valve

- Cross

- Cap

- Swage Nipple

- Plug

- Bush

- Expansion Joint

- Steam Traps

- Long Radius Bend

- Flanges

From the chart above that displays the standard pipe fittings, you can see the most common ones. These standard fittings are either forged or wrought. Wrought fittings are produced only from seamless pipes. The plate is used to manufacture large-diameter welded fittings.

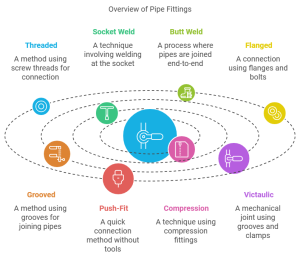

These fittings are available for the following types of end connections.

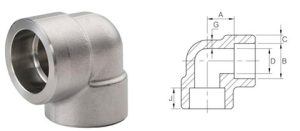

Pipe Elbow

Pipe elbow is a pipe fitting that allows changes in direction of flow in any pipe system, plumbing or otherwise. It helps redirect the fluid or gas in the desired direction. Elbows are important elements of a wide range of piping systems, such as water, gas and oil distribution systems. There are many types, angles and materials that are designed to suit a particular use.

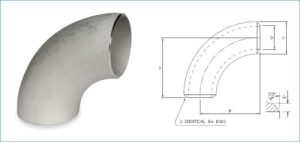

90° Elbow

A 90° elbow is a type of pipe fitting with a 90-degree angle bend, commonly used to change the direction of flow in a piping system. This type of elbow is one of the most widely used fittings, ideal for making right-angle turns in various applications. Versatile to handle a wide range of residential, industrial and commercial uses as used in piping systems to provide smooth flow turns and angles for the flow of liquids or gases.

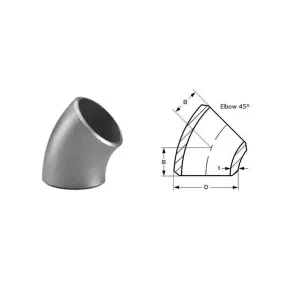

45° Elbow

A 45° elbow is a pipe fitting that bends the pipe at a 45-degree angle. It is used for moderate direction changes, providing a gentler turn compared to a 90° elbow. This fitting is ideal for situations where reduced resistance and smoother flow are needed.

Long-Radius Elbow

A long-radius elbow has a centerline radius that is 1.5 times the nominal size or diameter of the pipe. These elbows are commonly used in piping systems because they result in less pressure loss compared to short radius elbows. However, they require more space due to their larger size.

Short Radius Elbow

Short-radius elbows have a centerline radius equal to the pipe diameter. They are typically used in confined spaces where a sharper turn is necessary. While these elbows are ideal for space-restricted applications, they result in higher pressure drops due to the abrupt change in flow direction.

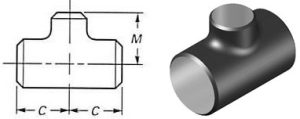

Tees Fittings

A tee is a type of pipe fitting that allows for the branching of a pipeline, typically forming a “T” shape. It has one inlet and two outlets, or vice versa, to connect pipes at a 90-degree angle. Tees are commonly used in piping systems to split or combine the flow of fluids or gases.

Equal Tee

This type of tee is fitted with three equal-sized outlets through which pipes of similar diameters are joined at right angles. It is widely used in systems that have an equal distribution of the flow through the branches.

Reducing Tee

In this type of tee, one of the openings has a smaller diameter than the others, allowing it to connect pipes of different sizes. It is used when there’s a need to reduce the size of the flow or branch off to a smaller pipe.

Side Outlet Tee

This type features an outlet on the side, allowing for a connection to be made at a 90-degree angle to the main pipe. It’s often used in specific applications where space or flow direction is critical.

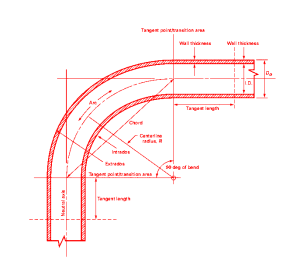

Pipe Bend

Long-radius pipe bends are often incorporated in the pigging of fluid transportation systems. These bends are characterised by low-pressure drops because of the increased radius that provides for an easy transition from one direction to another; this is important in the passage of the fluid and the pigging operations. Pipe bends are usually classified by the radius of the bend, and the most common types are 3D and 5D bends. Here, “D” represents the pipe’s diameter, with 3D bends having a radius three times the diameter and 5D bends having a radius five times the diameter.

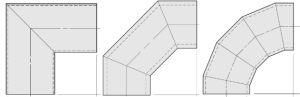

Miter Bend

Miter bends are custom-made from pipes and differ from standard pipe fittings. They are typically used for larger pipe sizes, usually 10 inches and above, as elbows of such sizes can be quite expensive. Miter bends are primarily recommended for low-pressure water lines. These bends are constructed by joining two, three, or five sections of pipe, allowing for a change in direction. However, due to their design, mitre bends are not suitable for high-pressure applications and are used mainly in less critical systems.

Cross

A cross, also known as a four-way pipe fitting, consists of one inlet and three outlets (or vice versa). While crosses are generally not used in process piping for fluid transportation, forged crosses are commonly found in firewater sprinkler systems. These fittings are meant to be used in particular flow rates and are usually applied where several connections are required in a single pipeline.

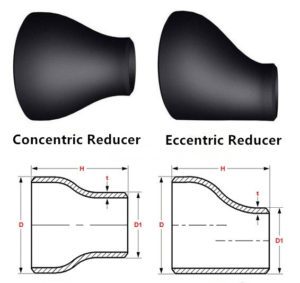

Pipe Reducers

Pipe reducers are pipe fittings used to connect pipes of different sizes, enabling a smooth transition between larger and smaller diameters. They are essential in systems where flow needs to be adjusted to suit different pipeline sizes. Pipe reducers help maintain the pressure and flow rate in pipelines, making them critical in many industries, such as oil and gas, chemical processing, and water treatment.

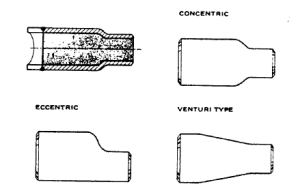

Concentric Reducers

A concentric reducer (or conical reducer) connects pipes of different diameters while maintaining the same centerline axis. It ensures a smooth flow transition and is used when the centerlines of the larger and smaller pipes must align, commonly in vertical and horizontal pipelines.

Eccentric Reducer

An Eccentric Reducer connects two pipes of different diameters, with the centre of each end on a different axis. It maintains the BOP (Bottom of Pipe) elevation, ensuring that one of the pipeline’s outer surfaces remains aligned. Eccentric reducers are essential when a consistent height or flat surface is required, particularly in horizontal pipe systems to avoid air pockets.

The offset is calculated as Offset = (Larger ID – Smaller ID) / 2.

Swage Reducer

A swage is similar to a reducer but smaller in size, used to connect pipes to smaller screwed or socket-welded pipes. Like reducers, swages are available in concentric and eccentric types. They come in various end types, including both plain ends or one plain and one threaded end, allowing for versatile connections in different piping systems.

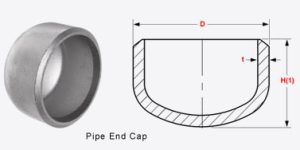

Pipe Caps

A pipe cap is a method utilized to end or terminate any pipe so that there would not be any difficulty in giving security against either contamination or damage or even any difficulty with regard to implementing a certain pressure onto the given pipeline. Pipe Caps are manufactured from different materials, including stainless steel, carbon steel and alloys and are available in numerous sizes and shapes to suit different uses. It can be threaded, welded or slip-on, which makes it easy to fit in place. Pipe caps are utilized in many industries, such as oil and gas, water treatment, and chemical processing, to isolate sections of pipes during maintenance, to provide a leak-tight seal, and to protect the pipeline.

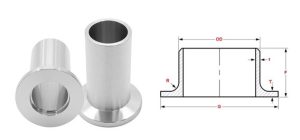

Stub Ends

Stub Ends are pipe fittings used with lap joint flanges. The stub end is butt-welded to the pipe, while the flange is placed over the stub end and can move freely. Although the stub end functions like a flange, it is classified under ASME B16.9 as a pipe fitting. This design allows for easier alignment and maintenance, making it ideal for systems that require frequent disassembly or where flanges are not welded directly to the pipe.

Piping Union

Piping Union is a type of pipe fitting used as an alternative to flanged connections, particularly in low-pressure, small-bore piping systems where frequent dismantling is required. Unions typically consist of three parts: a male end, a female end, and a nut. The male and female ends are threaded or socket-welded, and the nut provides the necessary pressure to seal the joint when tightened. Unions offer a convenient way to easily disconnect and reconnect pipes without the need for welding or flanged connections, making them ideal for applications requiring frequent maintenance or adjustments.

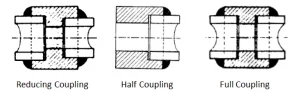

A pipe coupling is a short cylindrical piece designed to join two pipes of the same diameter so as to extend a pipeline or replace a section of it. It can be threaded or socket-welded and is often used in a range of piping systems to connect parts of the pipe or to act as a temporary solution when replacing a section of the pipe that has been damaged.

There are three different sorts of couplings:

- Full Coupling

- Half Coupling

- Reducing Coupling

Full Coupling

Full coupling is used to join two pipes of the same diameter. It has a hole in the centre to fit the pipe, and both ends are threaded or socket-welded, allowing for a secure connection.

Half Coupling

Half coupling is employed to join a pipe to another pipe of a smaller diameter, known as a branch pipe. It has one screwed or SW end, and the other end is plain to fit the pipe.

Reducing Coupling

Reducing (decreasing) coupling is applied to join two pipes of dissimilar diameters. It has different diameter at two ends so that it smoothly connects the large pipes with the small pipes. This type of coupling assists in the reduction of the flow size without compromising the pipeline’s construction.

Pipe Nipple Fittings

A pipe nipple is a short pipe with male threads at one or both ends, used to connect two fittings or extend pipes. It is commonly used in low-pressure piping systems to join pipes, hoses, or valves.

Socket weld and Threaded Pipe Fittings

Socket weld and threaded pipe fittings are both forged products designed for different pressure-temperature ratings. These fittings come in sizes ranging from 1/8″ to 4″ NPS

and are available in four pressure-temperature rating classes:

- 2000 class fittings are produced only in the threaded type.

- 3000 and 6000 class fittings are available in both threaded and socket weld types.

- 9000 class fittings are produced only in the socket weld type.

These fittings are commonly used in small bore and low-pressure pipework, providing secure connections in various industries like oil and gas, plumbing, and chemical processing.

Socket Weld Elbow

Socket weld elbow is a type of pipe fitting used to connect two pipes at an angle, typically 90 or 45 degrees. It features a socket at one end, into which the pipe is inserted and welded. This type of elbow is commonly used in high-pressure applications, offering a strong and durable connection, especially in smaller-diameter pipes.

Threaded Pipe Fittings

Threaded pipe fittings are fittings that have internal or external threads, allowing them to be screwed onto corresponding threaded pipes. These fittings are commonly used in applications where pipes need to be connected or joined without welding. Threaded pipe fittings are available in various shapes, such as elbows, tees, couplings, and unions, and are commonly used in low-pressure systems for fluids or gases in industries like plumbing, gas, and HVAC.

Tee and Cross Socket Weld Type

Socket Weld Tee connects a pipe to a main pipeline at a 90-degree angle, forming a “T” shape, and is commonly used in small-diameter, high-pressure systems. A Socket Weld Cross connects four pipes at right angles, meeting at a central point, and is used in industrial applications where multiple connections are needed. Both fittings provide strong, welded connections.

Conclusion

Pipe fittings are considered to be very essential parts of piping systems. They allow for proper flow of fluids as they create secure connections and allow for changes in direction, size or rate of flow. The various types of fittings such as elbows, tees, reducers, caps, unions, and nipples provide unique solutions for residential, commercial, and industrial use.

Different types of fitting such as socket-welded, threaded, and flanged are used for different purposes and work at different pressure and temperature. Knowledge of these fittings functions and application helps in designing and creating effective, leak free and efficient piping systems. From basic residential plumbing to complex industrial operations, pipe fittings are crucial for pipelines’ safety, maintenance, and longevity across various industries.