Alloy Steel F12 Forged Fittings Supplier

Alloy Steel F12 Forged Fittings, f12forged fitting exporter, Alloy Steel A182 F12 forged fittings, ASTM A182 GR F12 Alloy Steel Forged Fittings Manufacturer, Exporter & Suppliers, Alloy Steel Socket weld Pipe Fittings, Alloy Steel Forged Elbow Suppliers.

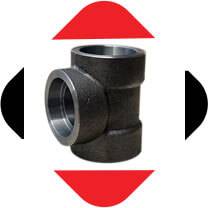

Alloy Steel F12 Socket Weld Fittings, Class 2000 LBS Grade F12 Cr-Mo Alloy Steel A182 Half Coupling Exporters, A182M Alloy Steel F12 ASME 16.11 Forged Full Coupling, Alloy Steel A182 Gr.F12 Forged Fittings, A182M Cr-Mo F12 Socket Weld Fittings

Table of Content

- What is ASTM A182 Alloy Steel F12 Forged Fittings

- ASTM A182 Alloy Steel F12 Forged Fittings Stock

- Alloy Steel F12 Forged Fittings Specification

- ASME SA 182 Alloy Steel F12 Forged Fittings Equivalent Grades

- Alloy Steel F12 High Pressure Forged Fittings Chemical Composition

- Alloy Steel F12 Forged Fittings Mechanical Properties

- Other Types of Alloy Steel F12 Forged Fittings

Simplex Steel Industries is one of the most prominent suppliers of Alloy Steel A182 F12 forged fittings. These fittings are made from high-quality raw materials with the help of modern technology. Alloy F12 forged fittings are generally known for their tensile strength and ability to withstand temperature variations. Our alloy steel forged fittings are accurately machined and have high dimensional accuracy, fine surface finish and surface roughness. Also, these A182 F12 forged fittings have a very high level of corrosion resistance and thus can be used in different oxidising and marine conditions.

We manufacture Alloy Steel Forged Fittings using modern techniques and advanced technology. As a leading F12 Forged Fitting supplier, our professional team keeps upgrading the methodology as per the market trends. Alloy Steel F12 Forged Fittings are in high demand because they are durable and require minimal maintenance. We aim to meet our client’s needs while staying ahead of the competition with the latest technology.

We use a standard method of packaging Alloy Steel A182 F12 forged fittings to avoid damages during transport.

What are Alloy Steel A182 F12 forged fittings?

Alloy Steel A182 F12 forged fittings are parts made from Alloy Steel A182 F12 using a forging method. They are used to join pipes, valves and other equipment in situations that involve high pressure and temperature.

What are the advantages of using Alloy Steel F12 forged fittings?

Alloy Steel forged fittings offer high strength, strong corrosion resistance and long-lasting durability. They can handle high temperatures and pressure, making them perfect for applications in the oil and gas industry.

What are the applications of Alloy Steel A182 F12 forged fittings?

Alloy Steel A182 F12 forged fittings are used in oil and gas, chemical processing and power generation industries. They are also used in boilers, heat exchangers and other equipment that operates at high temperatures and pressures.

Alloy Steel F12 Forged Fittings undergo strict quality checks to meet international standards, guaranteeing high-performance and long-lasting service. The fittings are available in various sizes and specifications, providing customised solutions to meet specific project requirements. With a focus on exceptional customer service, we guarantee timely delivery, efficient packaging, and competitive pricing.

Value Added Services

- Sand Blasting

- Electro Polish

- Epoxy Coating

Features

- High tensile strength

- Good load bearing capacity

- Excellent versatility and weldability

Testing

- Hardness Test

- Tensile Test

- Intergranular Corrosion Test

Alloy Steel F12 Forged Fittings Specification

| Standards | ASTM, ASME |

| Designation | A182, SA182 |

| Dimension Standard | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Grade | Alloy steel F12 Forged Fittings. |

| Type | Socketweld Fittings, Screwed-Threaded Fittings |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Size | 1/2" NB TO 48" NB. (Socketweld & Screwed-Threaded) |

| Types of Forged Fittings | Elbow, Tee, Union, Cross, Swage Nipples, Coupling, CAP, Plug, Bush. |

ASTM A182 Alloy Steel F12 Forged Fittings Types

ASME SA 182 Alloy Steel F12 Forged Fittings Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | Trade Name |

| Alloy Steel F12 | K11562 / K11564 | 1.7335 | 1Cr-1/2Mo |

Alloy Steel F12 High Pressure Forged Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F12 | 0.10-0.20 | 0.40-0.65 | 0.50 - 0.80 | 0.025 | 0.040 | 1 - 1.5 | 0.044 - 0.65 |

Alloy Steel F12 Forged Fittings Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| Alloy Steel F12 | 205 | 415 | 20 |

Alloy Steel F12 Forged Fittings Stock

- Alloy Steel F12 Socket weld Elbow

- Alloy Steel F12 Forged Tee

- Chrome Moly F12 Full Coupling

- Alloy Steel F12 Coupling

- Alloy Steel F12 90 deg. Threaded Elbow

- Alloy Steel F12 Half Coupling

- Alloy Steel K11562 Union

- Alloy Steel F12 Forged Cross

- Chrome Moly F12 Forged Pipe Nipple/Reducing Nipple

- Alloy Steel F12 Bushing

- CrMo F12 Threaded Unequal Tees

- Alloy Steel 1.7335 Forged Fittings in Mumbai

- Chrome Moly F12 45 Degree Forged Elbow

- Alloy Steel F12 Forged Fittings Supplier in Mumbai

- CrMo F12 Forged Fittings Manufacturer in India

- Alloy Steel F12 Equal Cross

- CrMo F12 Reducing Cross Stockholder in India

- Alloy Steel UNS K11562 Reducing Tee

- Chrome Moly F12 Forged Welding Boss

- CrMo F12 Forged End Cap/Pipe Cap

- Alloy Steel F12 Forged Reducers and Reducer Inserts

- Alloy Steel 1/2Mo Forged Fittings in India

- CrMo F12 Forged Tee Stockist in Mumbai, India

- Alloy Steel 1.7335 Forged Plug

- Alloy Steel F12 High Pressure Forged Fittings

- Alloy Steel F12 Industrial Forged Fittings

- CrMo F12 Socket weld Fittings

- Alloy Steel F12 Threaded Fittings

We have huge experience of supplying to all major industries across the world. These Forged Fittings is use in various industries like : Petrochemical, Pulp And Paper Co, Oil and Gas, Chemical Industry, Food Processing Industry, Plumbing, Water Supply Systems, Power Plant, General Purpose Applications, Fabrication Industry etc

Central/South America, North America, Asia, Mid East/Africa, Eastern Europe, UAE

Sri Lanka, Bahrain, Russia, Egypt, Portugal, Turkey, Spain, Singapore, Brazil, Thailand, Chile, Malaysia, Venezuela, Indonesia, Costa Rica, Poland, USA, U.A.E, Italy, Oman, Canada, Saudi Arabia, Angola, Qatar